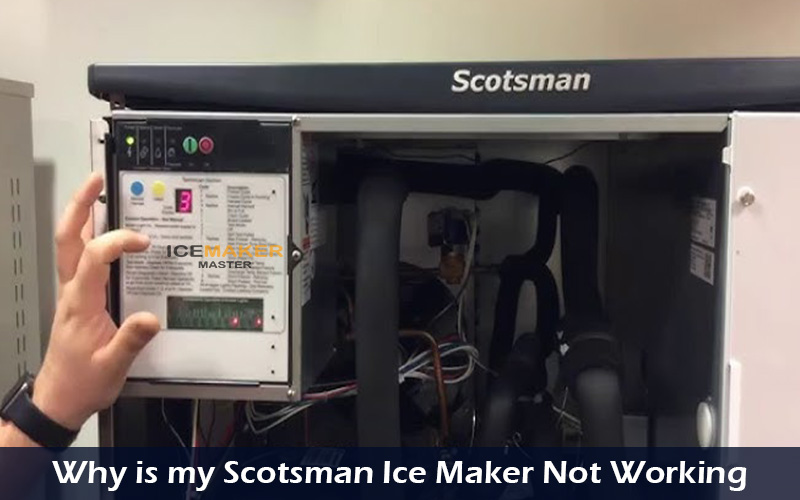

Every now and then, we may not pay attention to the laboriousness of an ice maker until it breaks down suddenly, denying us cooling blocks. This machine is a trusted partner for producing clear ice that comes in hand when you need something cold during a hot day. (Refer – For other ice maker)

Sometimes it can stop working like any other electric appliance and then there is a common question arises which is “Why is my Scotsman ice maker not working” which is more than a mere inconvenience as it disrupts the harmony of our routine.

Scotsman is renowned for quality, and raises expectations, making a malfunctioning ice maker all the more puzzling. In this blog, we will look into why a quiet Scotsman ice maker might not be working and explore the possible problems, and provide useful solutions for them. Let’s start our blog and if you face this issue then read this blog carefully and you will get the solution for your ice maker issue.

Common Issues and Their Possible Causes

No Ice Production

If your ice maker refuses to make any more ice, there are various possibilities. One reason could be that the water supply to the machine is not sufficient. This could be due to low water pressure or other issues.

Another possible cause might be a defective water inlet valve which controls water flow into the ice machine. Alternatively, impurities allowed into the machine through a faulty water filter can affect the quality of produced ice.

To fix these problems as well as restore ice production, start by checking the water supply to affirm that its quality meets set standards. Then inspect the water inlet valve for possible damage or malfunctioning and replace it if necessary. Lastly, swap out the water filtration system so that clean and uncontaminated fluid enters your home’s system while contributing to effective high-quality cube production in this regard.

Ice Maker Not Turning On

When the ice maker does not start, there are several things that may be causing it. Power supply problems can be one of the main reasons why and so it is important to establish if the unit has access to continuous power.

Furthermore, there might be a defective control module that controls how ice is made. Therefore one should examine this module for any visible damage or defects. Another cause could be a faulty on/off switch that may prevent the ice maker from starting its operations once it is damaged.

You should confirm that your appliance’s on/off switch operates without hitches for easy initiation and deactivation of an ice producer. These potential issues are systematically addressed in order to identify exactly what the problem is and what needs to be done in order to bring life back into the machine and make it work again as expected.

Also Read - How To Clean Scotsman Ice Maker

Loud or Unusual Noises

Several components may be involved if your ice maker is making loud or unusual noises. For instance, a broken evaporator fan can cause this. Also, the noise could be caused by a worn out condenser fan.

Another possible reason is a non-working water pump thus hampering the working of the ice maker as a whole. This necessitates an extensive examination to identify the specific component causing the noise. Once found, replace it for quieter operation.

Regular servicing and immediate replacement of worn-out parts will keep not only your ice maker very silent but also increase its efficiency and lifespan.

Ice Cubes Are Too Small or Irregular

In fact, there can be several reasons why your ice cubes may become smaller or irregular. Lower water pressure is one of the main causes of ruining the formation of ice. The resolution of this problem requires considering water pressure and ensuring that it is sufficient.

Another possible reason could be a clogged water inlet valve that affects the flow of water for proper ice formation. Cleaning the water inlet valve frequently can help correct this malfunction.

Moreover, another possible cause may include a defective thermostat which determines the sizes and uniformity of these ice pieces. For example, you need to examine whether your thermostat has any strange features and then decide whether you should buy a new one or not. After going through all these processes systematically, better results can be obtained from such an exercise.

Ice Melting Too Quickly

If your ice melts too fast, several things could be causing this to occur. One of these is the wrong temperature in the freezer environment which makes it impossible for the ice to stay solid. To fix this just adjust the freezer temperature to a level that will ensure optimal ice preservation.

Another factor is inadequate insulation which allows external heat to reach the ice. Therefore, improving insulation in and around the refrigerator can help maintain a colder environment.

There is nothing like a malfunctioning door gasket that could ruin an air tight seal and let warm air into a fridge. Regularly check and if need be substitute door gaskets, so as to have a perfect fit and stop the fast melting of ice.

Leaking Water

When water extraction is noticed in an ice maker, several elements are capable of contributing to this. A faulty water line may be the root cause allowing water to run down and collect around the device.

Another thing that could initiate it is a defective water inlet valve, which regulates the flow of water coming from the ice-maker. Moreover, impeded drainage of excess water might be caused by a blocked drain pump resulting in leaks.

It is crucial to examine these through performance checkup. Replace any damaged water lines; look for malfunctions in the water inlet valve and unblock the drain pump so that it can drain off used or surplus liquid efficiently.

Step-by-Step Troubleshooting Guide

If you cannot find the actual problem in your ice makers, then I recommend you to examine the entire ice maker. This troubleshooting guide will come to your aid for making this examination. Just follow below given instructions and find a solution for your ice maker.

Check the Power Supply

First of all, ensure that the Scotsman ice maker is plugged in correctly and check whether the power outlet works properly or not to rectify this issue. If the unit does not respond, it is necessary to assess thoroughly the energy source that might have created the power failure and fix it accordingly.

The basic tests of secure connection and functional electricity point are needed for identifying any probable sources obstructing normal operations of ice makers.

Inspect the Water Supply

To fix your ice maker, inspect the water supply to ensure that it is constant and enough. A reliable and adequate water supply is essential for the efficient production of ice. The ice maker may become inefficient because of low water pressure or problems with the water line.

Confirmation of a steady flow of water ensures that there are no factors that prevent an ice maker from offering its services as expected by its owner. When you address issues concerning water pressure or potential problems in the line, it is a step towards ensuring the overall functionality of the machine.

Also Read - Learn about EVOLUTION OF HOME ICE MAKER

Examine the Water Inlet Valve

The water inlet valve is the one that controls the flow of water into the ice maker and it needs your attention when fixing the ice maker. Observe keenly for any possible blockage and malfunctioning that may disrupt smooth water flow.

You should therefore address them promptly whenever you notice any problems such as clogged pipes blocking the movement of water or faults that interfere with its overall productivity. Thus, replacing the Water Inlet Valve in such cases can be a great way to ensure optimal performance.

It also helps to check on this and guarantee that it is operating well to make sure there is no interruption of water supply, thereby making it efficient in creating ice at will.

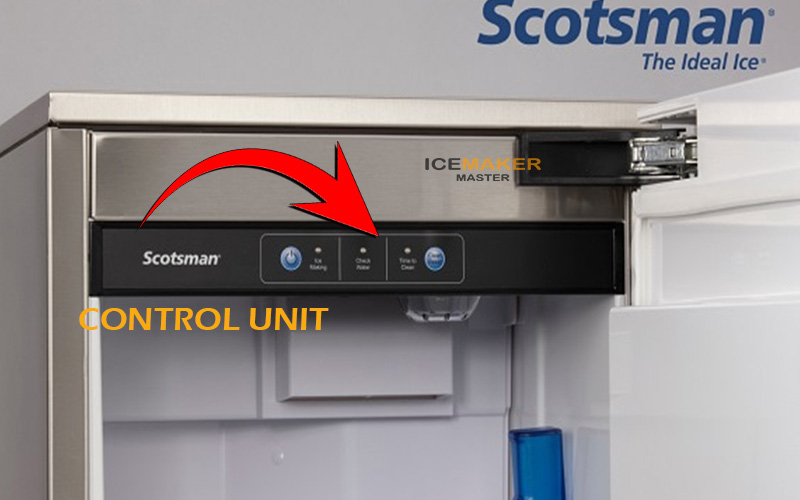

Evaluate the Control Module

This is where your ice maker gets instructions from, so it really is the ice maker’s brain. If you see any visible damage on the control module or signs of not working well, then you should try to fix it.

When abnormalities are noticed like physical damage or evidence of not being in order, they should be attended to immediately because the control module plays a major role in coordinating all functions of an ice-maker and any slight hitch in its functioning can interfere with the whole process of making ice.

It could still produce ice without any problem if you keep checking and maintaining its condition.

Review Freezer Conditions

First of all, it is very important to review your freezer conditions so as to continue enjoying optimal ice production. The best way is by checking if your freezer temperature is set right and making any necessary adjustments to follow the recommended settings.

Moreover, carry out an examination of the entire system to identify any possible concerns that may be causing problems in the formation of ice. It is important that a perfectly calibrated freezing point of refrigerants be maintained for efficient crystallization of water into ice.

This prevents malfunctions in the device and ensures that it produces hygienic large cubes on regular basis.

Clean Components

This is why you need to regularly clean some key components in your ice maker if you want it to be consistent and efficient. These include condenser coils, water lines, and ice bins.

Such regular maintenance prevents the accumulation of debris, dust or other things that may cause clogs or breakdowns. Unobstructed heat dissipation occurs when the condenser coils are clear thereby helping the ice maker perform efficiently.

Water lines that are cleaned consistently make sure water flows unimpeded hence supporting ice formation. Cleanliness of the ice bin ensures that dirt is not carried into the produced ice. Hence by observing such cleaning practices during your maintenance routine, you will prevent future problems from occurring.

Confirm Proper Insulation

Efficient insulation is required to prevent quick thawing of ice in your ice maker. Carry out a thorough check to ascertain that the insulation is enough and working in its best condition. When the insulation gets insufficient, maintaining a consistently cold environment within the ice maker becomes difficult; thus it causes the ice to melt faster.

Rectify any identified shortcomings or problems observed during an inspection by enhancing insulation immediately. This may involve gaps sealing, strengthening layers of insulators or dealing with all sources that allow heat entry into the system. Proper insulation ensures a controlled, stable space in which you can keep an ice maker.

Check Evaporator and Condenser Fans

It is very important that you regularly inspect your ice maker’s evaporator and condenser fans to enable it to perform optimally. You should check for signs of damage or wear in both fans that could cause them to stop functioning properly. Unusual noises or disruption of the cooling process may be an indication of issues with these parts.

Replace the faulty parts immediately if any. With the evaporator fan being essential for air circulation within the unit while the condenser fan assists in heat dissipation.

Fixing such problems with your fans means that you will have quieter surroundings as well as a more efficient and long-lasting ice maker.

Test the Thermostat

For the ice maker thermostat, check if it is operating at the desired temperature for the best production of ice. To ensure that cooling is properly regulated in an ice maker requires a thermostat that works well.

If you see any deviations or find out that the thermostat does not maintain the set temp as expected take action immediately. The temperature regulation device in this case plays an important role in creating conditions for ice formation thereby, influencing characteristics and uniformity of produced ice.

Inspect Door Gasket

Examining your ice maker’s door gasket carefully is vital for dealing with possible issues of thawing. The door gasket which shuts tightly when the door is closed, plays a key role in keeping a cold atmosphere suitable for ice conservation.

If at any point during the inspection, you see anything out of place such as wear and tear, damages etc., it becomes necessary to change the door gasket immediately. Damaged gaskets allow warm air into an ice maker thereby speeding up the melting process.

By keeping the integrity of a door gasket intact, one ensures efficiency and effectiveness of an icemaker while preventing unnecessary problems and ensuring that an appliance lives long.

Seek Professional Help

However, there are instances where expert attention becomes necessary even when this troubleshooting guide addresses many common problems associated with your ice maker. If your attempts to troubleshoot do not fix the issue or you are unsure about specific repairs, it’s better to consult a certified technician instead.

Professional help ensures that complex issues are accurately diagnosed and effectively addressed. The knowledge and tools needed to handle complicated problems are available only with certified technicians who know how to avoid possible damage or misdiagnosis.

FAQ

Why won’t my Scotsman ice maker make ice?

This could be due to a number of factors including a bad water supply, problems with the water inlet valve or a damaged thermostat. Give them attention and provide necessary troubleshooting.

How often should I service my Scotsman ice maker?

Clean condenser coils, water lines and the ice bin frequently to avoid blockages and malfunctions. Cleaning is part of routine maintenance.

At what point do I need assistance from a technician for my ice maker?

If you have tried troubleshooting but it doesn’t help or if you aren’t comfortable doing some repairs yourself, contact a certified technician in this field who can provide professional advice.

What can cause my Scotsman ice maker’s thermostat to go wrong?

The thermostat could become faulty due to regular wear and tear or electrical faults. Its accuracy might be affected by age and use leading to temperature control issues.

Which maintenance activities should I observe on my Scotsman ice maker?

Clean regularly items like condenser coils, water lines and the ice bin. Also, check for worn out/old parts which need replacement so that your machine functions best.

Conclusion

Fixing an inoperable Scotsman ice-maker might sound like a difficult task but it is not as difficult as it seems. This blog post will help you identify some common problems with your machine and how to fix them. Make sure that you have regular check-ups, and immediate identification of problem areas so that you can solve them on time hence ensuring that your Scotsman ice maker always gives the frosty perfection that one desires.

The smooth operation of the ice maker depends on knowledge about its parts, frequent maintenance, and prompt response to any challenges. This information should enable you to get enough ice anytime at all.